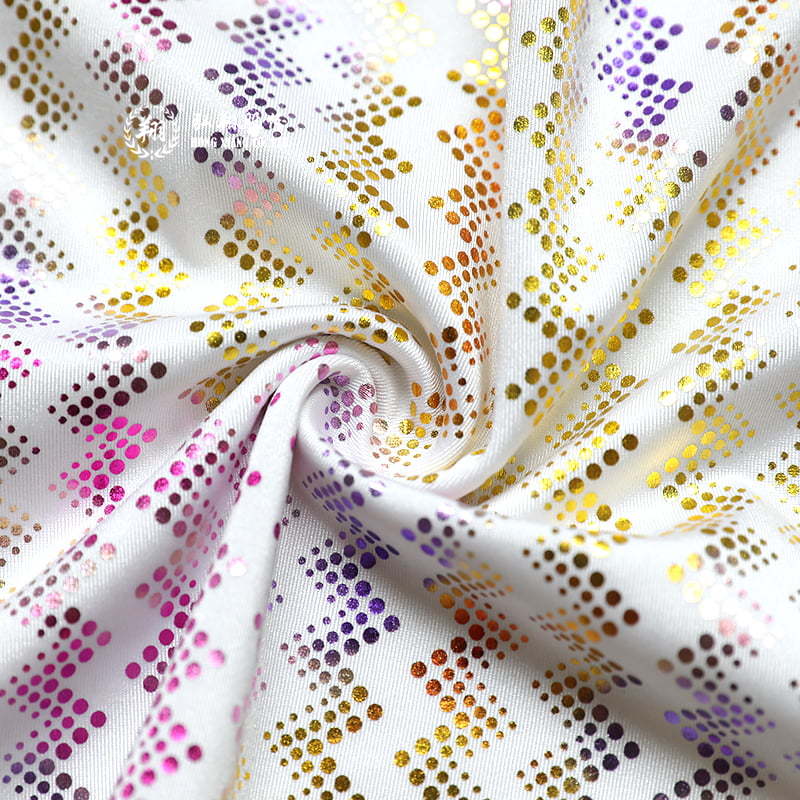

The printing of advertising sweater knitted fabric has developed rapidly in just ten years, but because its dimensional stability is difficult to control during processing, it is difficult to develop the rotary screen printing of knitted fabrics, especially knitted fabrics containing spandex, in addition to the cotton knitted fabric itself In addition to the drape weight of the cloth and the tension of the cloth feeding frame, it is also affected by the tensile force of the speed change. The shape and size of the pattern are more difficult to control, and it is more difficult to maintain the original shape when encountering geometric patterns. In some spirits, it is difficult to achieve satisfactory results. It is necessary to take necessary control over the whole processing process to solve it. Printing process of spandex-containing knitted fabrics. Weaving and rolling → loosening → (steaming)-presetting-pretreatment-+(dyeing)-→printing-→steaming-+washing-+dehydration-→drying-setting. The processing method of color separation design draft. Computer color separation of drawings, first of all, according to the variety of fabrics, elastic size and pattern return, number of sets, printing methods (direct printing, pull printing, anti-printing), shades of color, and scale the drawing to meet the production requirements. Specification. Scaling of print size. Under the conditions allowed by the return position. Generally, when the spandex content in cotton spandex is between 3% and 5%, the conditions of the entire printing process must be considered. Various parameters of rotary screen printing have been formulated at the same time of drafting. The printing speed of the above data is applicable to be controlled between 30 and 40 m/min. If the printing speed is above 50 m/min, the warp elongation ratio of the flower shape is required to be larger, but the general printing speed is below 40 m/min. It is easier to control the quality. Compared with woven fabrics, knitted fabrics have looser weaving and better permeability. Therefore, it is slightly different from the woven cloth printing draft when dealing with the drawing.

In the dye direct printing of knitted fabrics, the permeability of the printing paste is relatively good, generally 8 to 16 filaments of complex color, if the mechanical accuracy of the printing equipment allows, 8 filaments are better to ensure the printing accuracy, and at the same time in the processing When overlapping color printing, try to reduce the full cover of three colors to prevent the printing from being pressed: the anti-print printing has anti-reactive paint and active anti-active. The color separation draft, the size is drawn according to the requirements of the color draft, and the active flower draft is fully covered with the paint; when the active anti-reactive printing is used, the printed colors should not overlap each other as much as possible, but the white part can be covered as a whole. It can increase the color brightness of the colored parts, and will not produce white edges caused by printing.

In the processing of color separation and drawing, in addition to the above requirements related to the printing effect, the general processing principle is to conform to the spirit of the original, repeating the style of the flower draft on the cloth. The mesh of nickel mesh is selected according to the fineness of the pattern and the permeability of different fabric thicknesses. Nickel mesh is an indispensable material for printing. Currently, the commonly used nickel mesh meshes are 40, 60, 80, 105. 125 , 155, etc. The penetration rate of the nickel mesh is an important indicator. Of course, the actual size is also related to the viscosity of the slurry, the size and pressure of the scraper or magnetic bar, the printing speed, and the fabric. However, compared with woven fabrics, knitted fabrics have a rougher texture, so for printing the same pattern, the mesh selected for printing knitted fabrics can be larger than that of woven fabrics. 125 mesh and 155 mesh are mainly used for printing particularly fine patterns. If it is terry cloth plush or velvet printing, the fineness of the printing will be affected by the texture of the cloth surface. No matter how high the mesh is, it is difficult to reflect the effect of printing fine patterns. host. Therefore, the choice of the purpose of the nickel mesh mainly depends on the specific situation of each factory.