From the raw fiber materials to the final manufacturing of the finished fabric, it involves processes such as spinning, weaving, and dyeing, and each of these processes requires multiple consecutive processing steps to be completed. During each level of processing, improper setting of conditions, careless operation by personnel, and mechanical failures, etc., may all cause appearance defects in the products. Therefore, when we produce textile fabrics, we often encounter various flaws, resulting in substandard quality. The common problems in fabric inspection include:

1. Hole

The warp and weft yarns of the fabric break, resulting in holes of different sizes. This defect is prone to occur in fabrics with denser warp and weft yarns.

2. Dirty mark

Spots, drug contamination, drum contamination, foam contamination, color differences, water stains, white spots, and other dirtiness.

3. Broken Ends

If one or more of the warp yarns of a fabric break, the distance between the two adjacent yarns on either side of the break will increase. In a plain weave fabric, the two broken yarns will lie side by side, resembling a double warp. In a twill fabric, there will be a discontinuity in the fabric pattern.

4. Broken Pick

The weft yarn in the fabric breaks, but the two ends of the break are very close to each other, meaning the length of the break is relatively short. Such defects are generally not very noticeable.

5. Coarse End

Due to poor stretching during spinning, the fibers aggregated to form local thickened areas.

6. Coarse Pick

Due to issues with the yarn quality or the manufacturing process, there is a distinct horizontal thick line that stands out prominently when compared to the surrounding weft yarns.

7. Filling bar

After dyeing, the surface of nylon fabric will develop horizontal stripes.

N203TW4-B Nylon spandex matte long silk screen printing underwear fabric

JN191PY2 Nylon spandex bright mesh jacquard underwear fabric

T176TW8 Polyester matte jacquard underwear fabric

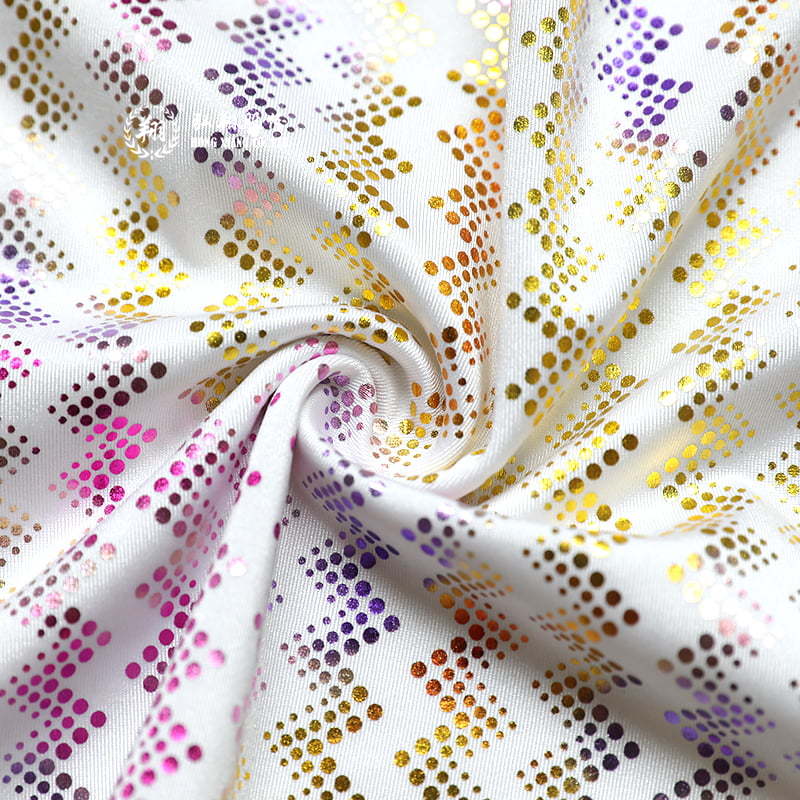

T001PY2-E Polyester bright hot color fashion fabric

T009PW6-E Polyester matte hot color fashion fabric

T004TB6-E Polyester semi-gloss hot color fashion fabric

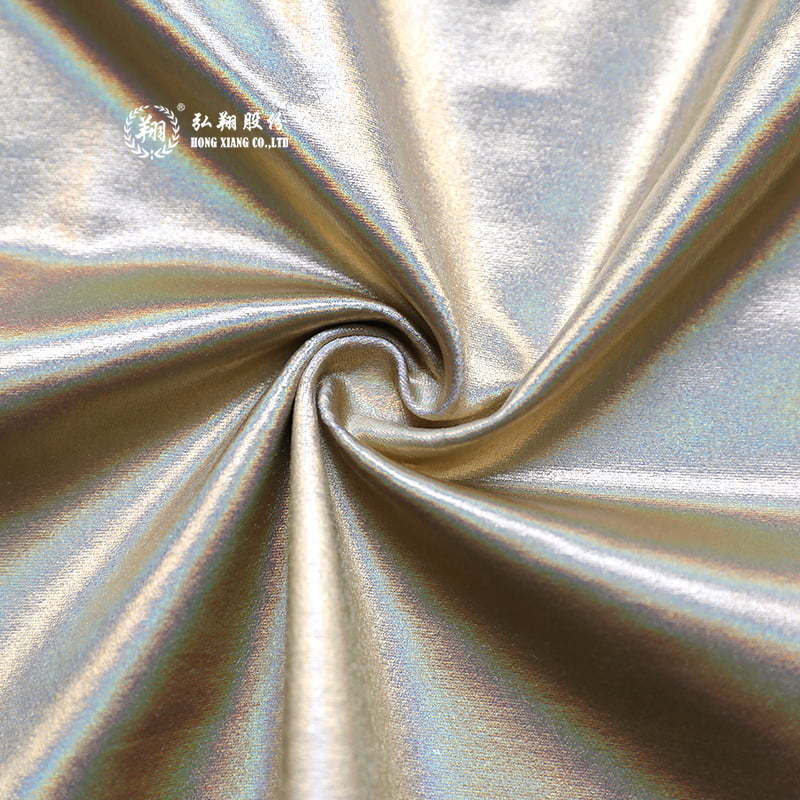

N001PY6-Z Jinyouguang flocking fashion fabric

N001PY6-A Jinyouguang Digital Printed Fabric swimsuit fabric

T009PW6-A Polyester matte digital printed swimsuit fabric

T009PW6-A Polyester matte digital printed swimsuit fabric